Love them or loathe them, the building regulations exist to ensure all building work undertaken is safe and correct. And as the installation of a stove and flue system is considered ’building work’, there is an extensive list of regulations an installer must comply with… Namely Approved Document J of the Building Regulations 2010 for England and Wales.

This is a brief overview of the kind of subjects covered by Approved Document J and is by no means the exhaustive list. For full understanding and compliance, be sure to clear a few hours of your life and check out the full document here.

What is Covered by the Building Regulations?

In short, everything! From initial notification of intended work through connections, types and heights of flue to ventilation, hearths and CO alarms, no stone is left unturned. So let’s dive in and address the points common to all stove and flue installations.

Notification of Work

It is always advised to use the skills and knowledge of an engineer registered with a self-certification scheme such as HETAS. They will (in theory) ensure all work is undertaken inline with the regulations and provide certification upon completion. If, however, you choose to self-install or use a non-registered tradesperson, your local Building Control Body (BCB) must be informed of your intentions prior to any work starting.

Do You Live in A Smoke Control Area?

You can find this out through the government website or your local council and is essential in dictating which type of stove you are permitted to install (DEFRA approved, non-DEFRA, EcoDesign).

Air Supply

Have you considered that your log burner requires a permanent supply of fresh oxygen for combustion and effective operation? Seems obvious but often overlooked, permanently open fire bricks or ‘ventilators’ must be installed in the room containing the stove. The only method to avoid this is with a direct air compatible burner that draws fresh air directly from outside the home and into the fire box. See our range of Rytons Air Core Vents here.

Provision of Flues

Hopefully we are aware that a closed heating appliance does not work without a flue? But did you know the way flue pipes connect together is covered by the regs? The female socket must always face upwards to contain moisture within the system, it has nothing to do with leaking smoke or gases. All joints of a system must be accessible for inspection, Flexible Flue Liners are for relining existing chimneys only and you are not permitted to pass your system through your neighbour’s home!

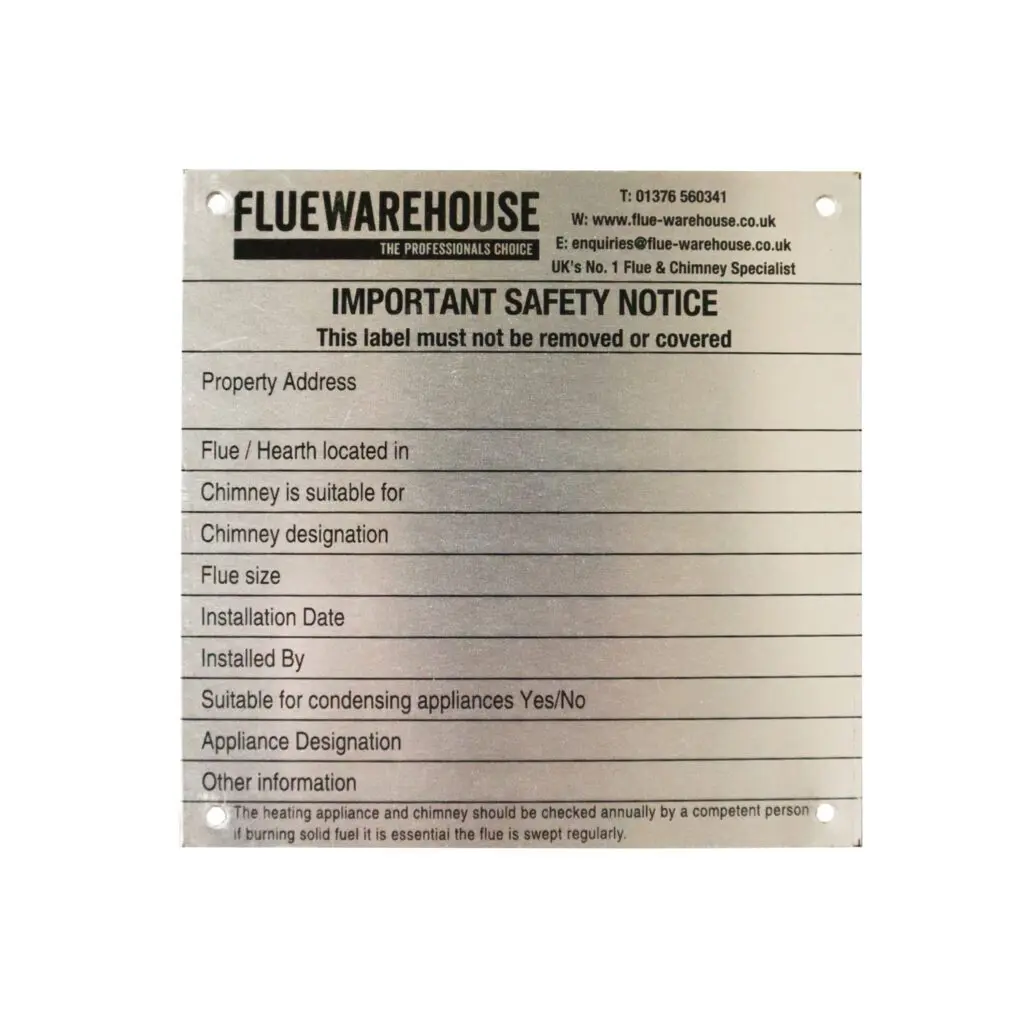

Notice Plates

Upon completion of a stove and/or flue installation, a Chimney Notice Plate must be filled out and permanently available by law. This plate contains details regarding the stove, flue and hearth to inform new owners of the property or anybody inspecting the system as to what has been installed and what British Standards have been met.

Bends in Flues

Every turn in a flue system is an obstruction to the hot gases rising and so the regulations limit the number permitted in any one system to a maximum of four. And in addition to this, the maximum angle of any bend is set at 45° to give the gases the best chance to continue rising. Therefore, 90° (right angle) Elbows are not allowed in a flue system, nor are horizontal runs with the exception of a maximum 150mm horizontal run from the rear outlet of a stove. 90° Tee Pieces with access caps are permitted if connected directly to the log burner.

Size of Flues

By ‘size’ they are referring to the internal diameter of pipework and this is established by two factors; the diameter of the stove outlet and if it’s DEFRA approved. A flue pipe must have an internal diameter equal to that of the stove’s outlet or larger but can never be smaller. So, if you have a stove with a large 8” outlet, then I’m afraid you are stuck with trying to install an 8” internal diameter flue.

DEFRA approved or Smoke Exempt stoves are permitted to have a reduced 125mm diameter flue due to their cleaner burning nature whereas non-DEFRA approved stoves must have a minimum 150mm flue. Both of these points however are subject to the size of the outlet collar as explained above.

Height of Flues

The height (or total length) of a flue system is important for two reasons; firstly, if the flue isn’t long enough, the stove will not operate correctly and secondly, the products of combustion need to be safely exhausted into open air and not yours or your neighbour’s upstairs window.

To provide sufficient draw for a closed heating appliance, it is advised a flue system be at least 4.5m in length. This is measured from outlet collar to underside of terminal.

And how high the flue must rise to ensure safe exhaustion is determined by the point the flue passes through or by the roof. As a rule of thumb, the two points to adhere to are 1) the top of the flue needs to have a minimum 2.3m horizontal clearance between it and the pitched roof and 2) must rise at least 1000mm once through the roof. There are caveats to this where ridges, windows, thatched roofs and nearby buildings are concerned, as highlighted in the image. Please also see our guide to Flue Draught and Minimum Flue Heights.

Distances to Combustible Materials

Flue pipes get hot so it’s not safe to run them too close to combustible materials such as wood and soft furnishings. This clear distance that must be maintained between the outer edge of an uninsulated stove pipe and all materials is of course dictated by the building regulations which state a distance of 3x the pipe’s diameter must be clear to combustible material and 1.5x the pipe’s diameter to non-combustibles. This is heavily reduced for insulated Twin Wall flue but is specific to the brand, typically 50-60mm.

Hearths

To prevent your home burning down or little ones touching the stove, a clear area must be created around a log burner aka the hearth. These fall into two categories: Constructional and Super-Imposed Hearths.

Constructional hearths are the type typically found in an existing fireplace and create a physical obstruction to accessing the stove (or a trip hazard depending on your point of view). These will be a minimum 125mm thick (or 250mm thick if no air gap is present) and are built into the construction of the floor and must measure at least 150mm wider each side than an exiting fireplace or 840x840mm for freestanding installs.

Super-Imposed hearths are minimum 12mm thick, typically slate, glass or tile and are permitted only for stoves that have been accredited as Cool Hearth Rated. This means they do not exceed 100°C at their base and so pose less danger to the floor.

Click here to view our extensive range of Hearths.

Carbon Monoxide Alarms

A Carbon Monoxide (CO) Alarm is a legal building regulation requirement, as is its location – 300mm away from a wall if on a ceiling and no closer than 150mm to the ceiling if installed on a wall. And it must be within 1-3m of the stove itself.

Approved Document J of the Building Regulations includes a handy checklist in the Appendixes (page 70) taking you through all of the above and plenty more, step by step, to ensure compliance alongside plenty of helpful diagrams to help get your head round the regs. They even suggest further reading material if you’re so inclined. Click here for the full document.